Introduction

Selecting the right site selection mechanicals is paramount for any successful construction endeavor. We’ve all heard stories, or perhaps experienced firsthand, the frustrating setbacks that arise when a project’s location is poorly chosen. Imagine a state-of-the-art manufacturing facility struggling with insufficient power supply, or a cutting-edge data center plagued by unexpected flooding – scenarios that could have been avoided with a more thorough site selection process.

Site selection, however, goes far beyond simply finding a plot of land. For mechanical engineers, it’s a critical factor that profoundly impacts system performance, construction expenses, operational costs, and the long-term sustainability of any project.

It’s about understanding how the chosen location will directly influence the efficiency, reliability, and overall effectiveness of the mechanical systems that are at the heart of any building or facility. Failing to prioritize these aspects can lead to costly redesigns, ongoing operational inefficiencies, and even project failure.

This guide aims to equip mechanical engineers with the knowledge and tools necessary to effectively navigate the complexities of site selection. We’ll explore the essential mechanical requirements that must be defined upfront, delve into infrastructure assessments (power, water, waste), and examine the crucial environmental factors that can significantly impact your designs. Furthermore, we’ll navigate the regulatory landscape, address logistical considerations, and analyze the true cost implications to ensure optimal integration of site selection and mechanical design.

Understanding Your Project’s Mechanical Needs

Before a single shovel of dirt is turned, a mechanical engineer must possess a crystal-clear understanding of the project’s fundamental mechanical requirements. This isn’t merely a matter of sketching out HVAC layouts; it involves a deep dive into the operational demands that will dictate the success or failure of the chosen location.

Accurately defining these needs upfront is paramount, as it forms the bedrock upon which all subsequent site selection decisions are made. Failure to do so can lead to costly retrofits, compromised system performance, and long-term operational inefficiencies.

One of the most critical elements to define is power consumption. Understanding both peak and average power demands is crucial for assessing the capacity of the local electrical grid. Considerations must extend beyond simply having enough power; reliability and redundancy are equally vital, particularly for facilities with mission-critical operations. Cooling and heating loads represent another significant area of investigation.

What are the expected BTU/hr requirements for maintaining optimal operating temperatures? Furthermore, specialized equipment often introduces unique demands, such as compressed air, process cooling water, or specialized ventilation systems. These needs must be thoroughly documented and translated into concrete site selection criteria.

To illustrate, consider the stark contrast between the mechanical requirements of a data center and a manufacturing plant. A data center is characterized by its massive and constant power demands, coupled with equally substantial cooling needs to prevent equipment overheating. Redundant power sources and sophisticated cooling systems are non-negotiable.

Conversely, a manufacturing plant may have fluctuating power demands depending on production schedules. Ventilation requirements may be more complex due to potential emissions or hazardous materials. Understanding these fundamental differences underscores the necessity of a project-specific approach to site selection mechanicals.

Infrastructure Assessment

Existing infrastructure plays a vital role in determining whether a site is suitable for a project. Mechanical engineers must thoroughly evaluate the available resources to ensure seamless system operation and prevent costly disruptions. This assessment encompasses power, water, and waste management, each requiring careful consideration.

Power Infrastructure

Adequate and reliable power is paramount. Evaluate the existing capacity, including peak and average demands, and redundancy measures in place. Determine the voltage and available substations, considering the feasibility of on-site power generation through solar, wind, or other renewable sources.

A crucial factor is assessing the reliability of the power grid at the location. Frequent power outages can cripple operations and necessitate expensive backup systems. Understanding the utility’s plans for future upgrades or expansions in the area is also vital, as this could impact the long-term availability and cost of power.

Water and Waste Considerations

Water availability, quality, and pressure are equally critical, particularly for cooling and industrial processes. Identify connection points and understand wastewater discharge requirements. Determine if the local water supply can meet your demands, and analyze the water quality to assess the need for pre-treatment processes. Moreover, proper waste management is essential for environmental compliance and operational efficiency.

Evaluate the methods for handling industrial waste, including hazardous materials, and the proximity to suitable treatment facilities. Familiarize yourself with relevant regulations and constraints related to waste disposal. Overlooking these factors can lead to significant environmental liabilities and operational challenges. A comprehensive evaluation of these infrastructure components is a cornerstone of responsible and effective site selection mechanicals.

Environmental Factors

The interplay between environmental conditions and the efficiency of mechanical systems cannot be overstated. Understanding these factors early in the site selection process is crucial for mitigating risks and maximizing long-term operational performance. Failing to account for these elements can lead to increased energy consumption, higher maintenance costs, and even system failures.

Climate Considerations

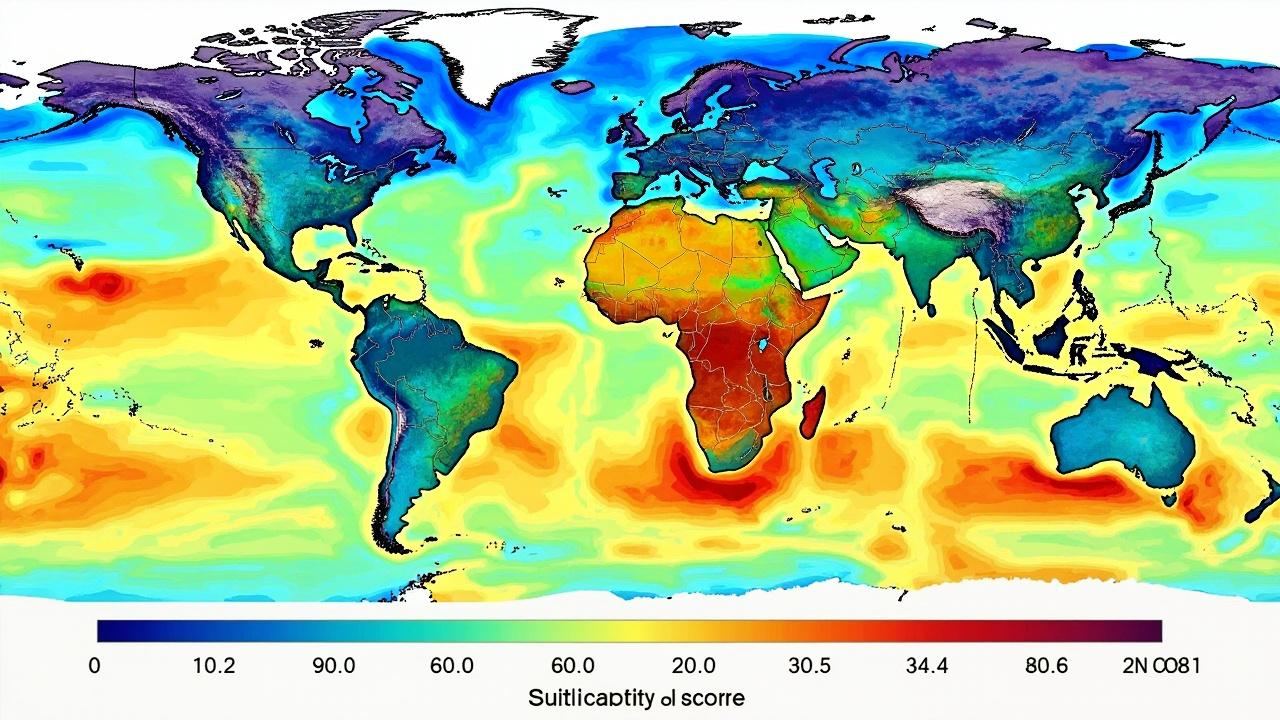

Climate plays a significant role in determining the heating and cooling loads of a building. Analyzing heating degree days (HDD) and cooling degree days (CDD) provides valuable insight into the expected energy demand for HVAC systems. For instance, a site in a region with high CDD will necessitate a robust and efficient cooling system, potentially influencing decisions about chiller types, cooling tower design, and the need for thermal energy storage.

Humidity levels also impact HVAC design, requiring consideration of dehumidification strategies and potential for mold growth. Furthermore, solar orientation and shading are critical factors in minimizing solar heat gain and reducing cooling loads. Effective utilization of passive solar design principles can significantly reduce energy consumption and improve indoor comfort.

Geological Considerations

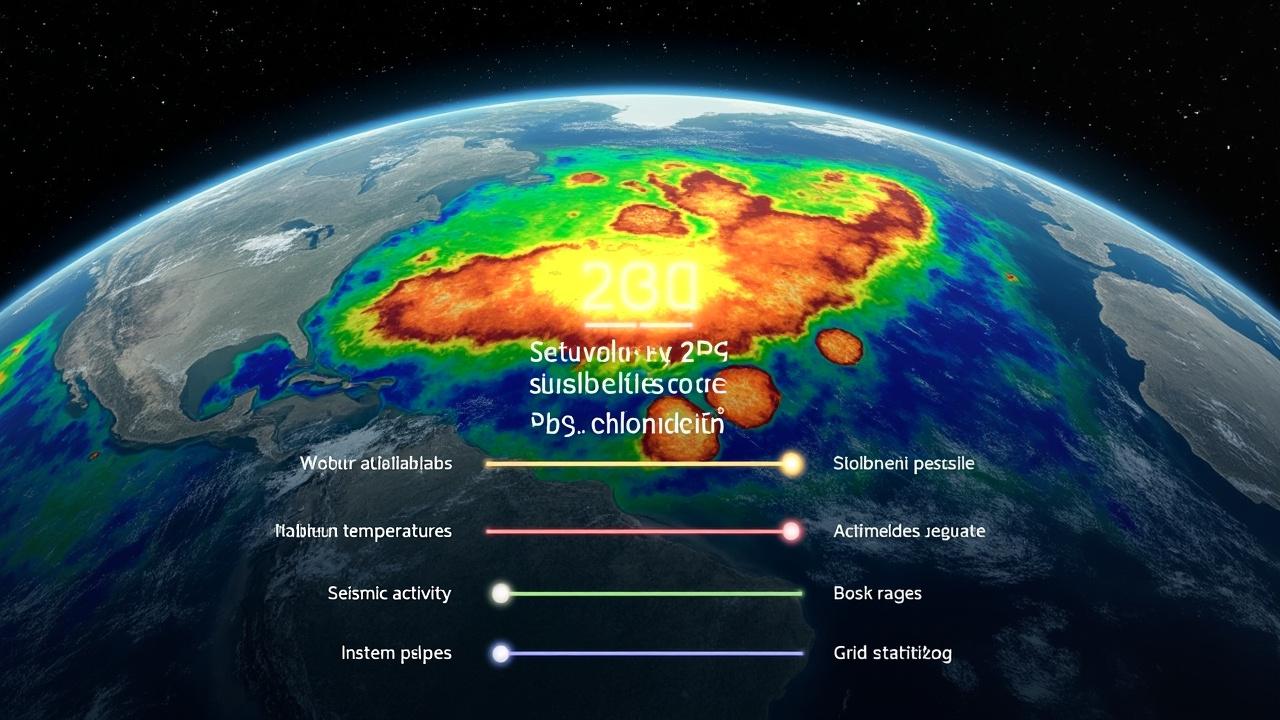

The geology of a site directly impacts the foundation design and stability of mechanical equipment. Soil bearing capacity determines the load-bearing capabilities of the ground, influencing the design of equipment pads and structural supports. Seismic activity is another critical consideration, particularly in earthquake-prone regions. Buildings and mechanical systems must be designed to withstand seismic forces, requiring specialized engineering and construction techniques.

Potential for soil subsidence or landslides must also be evaluated to ensure the long-term stability of the site and prevent damage to mechanical infrastructure. Groundwater levels can affect underground structures and piping, necessitating proper waterproofing and drainage systems. In addition, the composition of the soil can impact the corrosivity of buried piping and equipment, influencing material selection and protective coatings.

Natural Disaster Risk Assessment

Sites located in areas prone to natural disasters such as flooding, hurricanes, tornadoes, or wildfires require careful risk assessment and mitigation strategies. Floodplains must be identified and avoided, or buildings must be elevated to protect against flood damage. Hurricane-resistant construction techniques and wind-resistant equipment enclosures are essential in coastal regions. Tornado shelters or reinforced structures may be necessary in tornado-prone areas.

Wildfire risks can be mitigated by creating defensible space around buildings, using fire-resistant building materials, and implementing fire suppression systems. Conducting thorough environmental impact assessments (EIAs) and obtaining necessary permits are critical steps in ensuring compliance with environmental regulations and minimizing the environmental impact of the project. Ultimately, early consideration of these environmental factors and thoughtful site selection mechanicals integration leads to more resilient, efficient, and sustainable mechanical systems.

Regulatory Landscape

The regulatory landscape surrounding any construction project can be a complex web of codes, permits, and compliance requirements that directly impact the mechanical systems. Building codes, such as the International Building Code (IBC) and any local amendments, set minimum standards for safety and energy efficiency.

Mechanical engineers must be intimately familiar with these codes to ensure their designs meet the necessary requirements for HVAC, plumbing, and fire protection systems. Failing to adhere to these codes can result in costly delays, rework, and even legal penalties.

Obtaining the necessary permits for mechanical systems is another critical step in the site selection and construction process. This often involves submitting detailed plans and specifications to local authorities for review and approval. Inspections are typically required at various stages of construction to ensure compliance with the approved plans and applicable codes.

The timeline for obtaining permits can vary significantly depending on the jurisdiction and the complexity of the project, so it’s crucial to factor this into the overall project schedule. Understanding the permitting process early on can prevent unexpected delays and cost overruns.

Furthermore, environmental regulations play a significant role in site selection, particularly concerning emissions, waste disposal, and water usage. Mechanical systems often have the potential to generate air and water pollutants, so it’s essential to comply with all applicable environmental regulations. This may involve implementing pollution control measures, obtaining discharge permits, and conducting regular monitoring.

Accessibility requirements, such as those outlined in the Americans with Disabilities Act (ADA), must also be considered when designing mechanical systems to ensure that buildings are accessible to people with disabilities. Early engagement with local authorities is crucial to navigate these complexities and ensure compliance with all applicable regulations, ultimately impacting site selection mechanicals and building operations.

Proximity and Logistics

Proximity to key resources significantly impacts project success. Easy access to suppliers, customers, and a skilled labor pool should be a primary consideration. Reduced travel times for personnel and materials translate to lower operational costs and increased efficiency. Before settling on a site, conduct a thorough assessment of the available workforce in the area, considering their skills, experience, and prevailing wage rates. Evaluate the proximity to specialized service providers who can support the mechanical systems throughout their lifecycle.

Transportation infrastructure is paramount. Efficient road access is vital for deliveries and personnel transport, especially during construction when heavy equipment and materials are frequently moved. Rail access can be a major advantage for projects requiring the transport of bulk materials or finished goods.

For international projects or those relying on global supply chains, proximity to ports and airports can significantly reduce transportation costs and lead times. A thorough analysis should also include the availability of laydown areas and storage facilities, both during construction and for ongoing operations. Insufficient space for staging materials can lead to delays and increased costs.

Understanding the impact of transportation costs on overall project economics is crucial. Conduct a comprehensive analysis of freight rates, fuel costs, and potential delays associated with different transportation modes. Consider the availability of alternative transportation options and their respective costs and benefits. Finally, remember that effective site selection mechanicals must account for the long-term implications of logistical choices on the sustainability and profitability of the project.

| Factor | Importance |

|---|---|

| Proximity to Suppliers | Reduces lead times, lowers costs |

| Workforce Availability | Ensures access to skilled labor |

| Transportation Infrastructure | Facilitates efficient material and personnel movement |

| Laydown Areas | Provides space for material storage |

Cost Analysis

Initial site acquisition costs are just the tip of the iceberg when evaluating a location’s true expense. Mechanical engineers must delve deeper, considering the long-term operating costs that will significantly impact the project’s overall profitability. Overlooking these factors can lead to substantial financial burdens down the line, negating any perceived savings from a lower initial purchase price. A comprehensive cost analysis is crucial for making informed decisions.

One of the most significant ongoing expenses is energy consumption. Site location directly influences energy usage and utility rates. For example, a site in a region with extreme temperatures will require more energy for heating and cooling, increasing operational costs. Factors such as building orientation, insulation, and window efficiency also play a critical role.

Furthermore, utility rates vary significantly by location, and it’s crucial to research and compare rates from different providers. Investing in energy-efficient equipment and optimizing system design can help mitigate these costs. Beyond these considerations, another element of long-term costs, are site selection mechanicals.

Maintenance is another area where site selection plays a vital role. A site that is difficult to access or lacks adequate space for maintenance activities can lead to increased labor costs and equipment downtime. Availability of spare parts and proximity to qualified service technicians are also important considerations. Choosing equipment that is reliable and easy to maintain can further reduce maintenance expenses.

Finally, it’s essential to consider the potential for future expansion or upgrades. A site that is too small or lacks the necessary infrastructure to support future growth can limit the project’s long-term potential. Planning for future expansion during the site selection process can save significant costs and headaches down the road.

A thorough Total Cost of Ownership (TCO) analysis, which considers all of these factors, is essential for making a sound investment decision. Consider the following list of elements when determining long-term costs.

Site Selection Mechanicals

Integrating mechanical system design directly into the site selection process is crucial for optimizing performance and minimizing long-term costs. Often, site selection is viewed primarily through the lens of real estate and logistical considerations. However, a mechanical engineer’s perspective brings a vital understanding of how the site itself will influence the design, operation, and maintenance of critical building systems.

This proactive approach allows for design optimization based on the inherent opportunities and constraints presented by a specific location. For example, a site with access to a natural body of water could present the opportunity for a more efficient cooling system, while a location with high solar irradiance might make solar thermal or photovoltaic systems a viable option.

One of the primary benefits of early mechanical system integration is the ability to adapt the design to the site rather than forcing the site to conform to a predetermined design. This can lead to significant cost savings in the long run. This integration requires a deep understanding of the site’s microclimate, including temperature variations, wind patterns, and solar exposure. Consider a scenario where a building is situated on a site with prevailing winds from the north.

By strategically positioning the building and designing the ventilation system to take advantage of these winds, it’s possible to reduce reliance on mechanical ventilation and lower energy consumption. Similarly, the selection of building materials and the orientation of the building can be optimized to minimize solar heat gain in hot climates or maximize solar heat gain in cold climates. This requires close collaboration between the mechanical engineer, architect, and construction team from the earliest stages of the project.

Furthermore, forward-thinking designs will allow for future adaptability of the mechanical systems as technologies evolve. This could include designing systems that can easily accommodate the integration of renewable energy sources or incorporating modular components that can be upgraded or replaced as needed. Careful site selection mechanicals also includes provisions for future expansion.

By ensuring sufficient space for additional equipment or infrastructure, it’s possible to avoid costly retrofits or relocation in the future. The goal is to create a mechanical system that is not only efficient and reliable but also flexible and adaptable to changing needs and technologies.

| Consideration | Example | Benefit |

|---|---|---|

| Geothermal Potential | Site with favorable subsurface temperatures | Reduced heating and cooling costs |

| Solar Exposure | Site with unobstructed southern exposure | Opportunity for solar energy generation |

| Prevailing Winds | Site with consistent wind patterns | Enhanced natural ventilation |

Due Diligence

Before finalizing a site selection, thorough due diligence is crucial to uncover potential problems that could lead to costly delays, redesigns, or even project failure. This process involves a multi-faceted investigation to assess risks associated with the property. One of the initial steps is conducting comprehensive site surveys and geotechnical investigations.

These studies provide valuable data about soil composition, groundwater levels, and potential geological hazards. This information is essential for determining the suitability of the site for supporting the planned infrastructure and ensuring the stability of foundations.

Another crucial aspect of due diligence is reviewing historical data related to the site. This includes researching past uses of the property to identify any potential environmental contamination. Old industrial sites, for example, may have residual pollutants in the soil or groundwater that could pose health risks or require extensive remediation.

Title searches and legal reviews are also necessary to identify any existing encumbrances, easements, or other legal restrictions that could impact the project. Engaging qualified consultants, such as environmental engineers and geotechnical engineers, is highly recommended to conduct these investigations and interpret the findings accurately. All of this contributes to a more holistic perspective when it comes to *site selection mechanicals*.

Finally, it is important to engage with the local community and communicate with neighbors and other stakeholders. This can help identify any potential concerns or opposition to the project and allow for proactive mitigation strategies. Ignoring community feedback can lead to delays in permitting and construction, as well as damage the project’s reputation.

Here’s a list of some important things to do in order to conduct a thorough due diligence process.

- Site Surveys

- Geotechnical Investigations

- Historical Data Review

- Title Searches and Legal Reviews

- Community Engagement

Conclusion

In conclusion, selecting the optimal site transcends simply finding available land; it demands a holistic evaluation that intricately weaves together mechanical engineering principles, environmental considerations, and regulatory compliance. This guide has illuminated the critical areas requiring meticulous assessment, from infrastructure capacity and geological stability to logistical accessibility and life cycle cost analysis. By diligently addressing each element, mechanical engineers can proactively mitigate potential challenges, maximize system efficiency, and ultimately drive project success.

A comprehensive checklist serves as an invaluable tool during this process. Does the site’s infrastructure adequately support the project’s power, water, and waste management needs? Have environmental factors, such as climate and seismic activity, been thoroughly assessed and incorporated into the design?

Is the regulatory landscape clearly understood, and are all necessary permits and approvals attainable? Moreover, have logistical considerations, including proximity to suppliers and transportation infrastructure, been factored into the equation? Thoughtful consideration of these questions, combined with proactive engagement with stakeholders, forms the bedrock of informed decision-making.

Ultimately, the perfect site empowers mechanical engineers to design and implement systems that are not only efficient and reliable but also sustainable and adaptable to future needs. Remember that early integration of site selection mechanicals ensures system optimization.

By embracing a collaborative approach and leveraging the expertise of qualified consultants, engineers can navigate the complexities of site selection with confidence, transforming potential obstacles into opportunities for innovation and long-term success. Don’t hesitate to seek expert guidance in making these crucial decisions; the right site can pave the way for a thriving and sustainable future.

Frequently Asked Questions

What mechanical considerations are most crucial when selecting a site for a new building or facility?

When selecting a site for a new building, access for large equipment delivery and maintenance is paramount. Additionally, the load-bearing capacity of the ground must be sufficient to support the mechanical equipment, including chillers, generators, and air handling units. Vibration isolation and noise attenuation considerations are also critical to minimize disruptions to the building occupants and surrounding areas.

How does site orientation impact the design and efficiency of mechanical systems?

Site orientation directly impacts solar heat gain, which affects the cooling load demand of the building. Orienting the building to minimize direct sunlight exposure on east and west facades can significantly reduce the required cooling capacity. Furthermore, prevailing wind direction can be leveraged for natural ventilation or, conversely, must be accounted for when designing exhaust systems and preventing unwanted infiltration.

What soil conditions can affect the installation and performance of underground mechanical infrastructure?

Soil conditions such as high water tables can lead to corrosion and potential flooding of underground mechanical infrastructure. Unstable soil, including expansive clay, can cause shifting and damage to buried pipes and conduits. Rocky soil can increase excavation costs and complicate the installation of underground systems. Proper soil testing and analysis are essential to mitigate these risks.

How do local climate conditions (temperature, humidity, wind) influence site selection for optimal mechanical system performance?

Local climate conditions heavily influence the selection of mechanical systems and their operating efficiency. High temperatures and humidity increase the cooling load and necessitate more robust air conditioning systems. Strong winds can impact the performance of cooling towers and require careful placement to prevent recirculation. In colder climates, freezing temperatures necessitate freeze protection measures for outdoor equipment and piping.

What are the implications of existing utilities (water, gas, electricity) at a potential site for mechanical system integration?

The presence of existing utilities at a potential site can greatly impact the cost and complexity of mechanical system integration. Adequate capacity of existing water, gas, and electrical lines is crucial to avoid expensive upgrades.

The location and depth of existing utilities must be accurately mapped to prevent conflicts during excavation and installation of new mechanical infrastructure. Accessibility and tie-in points should be assessed.