Introduction

Ever notice your phone getting uncomfortably warm after a long gaming session? Or perhaps your laptop fan kicks into high gear just trying to stream a movie? This is the ever-present problem of heat, and understanding how to manage it is becoming increasingly vital in our technology-driven world. This article will explore a particularly effective cooling technology: two phase cooling.

Modern electronics, from smartphones to supercomputers, generate a significant amount of heat as a byproduct of their operation. This heat, if not properly dissipated, can lead to a cascade of problems. Overheating can severely impact performance, causing slowdowns and glitches.

More seriously, it can drastically shorten the lifespan of electronic components, leading to premature failure and costly replacements. Efficient cooling, therefore, isn’t just about comfort; it’s about ensuring the reliability, longevity, and optimal functioning of the devices we rely on every day.

Fortunately, engineers have developed a variety of methods to combat the problem of heat. From simple heat sinks and fans to sophisticated liquid cooling systems, these techniques aim to draw heat away from sensitive components and dissipate it into the surrounding environment.

But as technology continues to advance, and the power of our devices increases, traditional cooling methods are starting to reach their limits. This article will delve into the exciting world of two-phase cooling, a technique that leverages the power of phase change to achieve unprecedented levels of heat transfer efficiency.

What Is Heat? A Quick Thermodynamics Refresher

Heat, in its simplest form, is energy in transit. It’s the energy that flows from one object to another due to a temperature difference. Imagine holding a cup of hot coffee on a cold day.

The energy from the coffee, which we perceive as heat, is transferred to your hand and then to the surrounding air. This transfer continues until the coffee and the environment reach a state of thermal equilibrium, where they have the same temperature. So, heat isn’t something an object *has*, but rather something it *does* – it’s energy on the move.

Temperature, on the other hand, is a measure of the average kinetic energy of the molecules within a substance. The faster the molecules are moving, the higher the temperature. Think of it like a bustling crowd: the more energetically the people are moving, the higher the “energy” of the crowd.

Temperature provides a way to quantify the “hotness” or “coldness” of an object relative to a standard. It is critical for engineers to understand the precise temperature tolerances of equipment so that they can best design and implement cooling systems.

Now, how does this energy transfer actually happen? There are three primary mechanisms: conduction, convection, and radiation. Conduction involves the transfer of heat through a material, like the heat moving along a metal spoon when it’s placed in hot soup. Radiation is the transfer of heat through electromagnetic waves, like the warmth you feel from the sun.

For cooling purposes, convection is often the most important. Convection is heat transfer through the movement of fluids (liquids or gases). In traditional cooling, fans force air (a fluid) over hot components, carrying heat away. In sophisticated cooling systems like two phase cooling, the movement of the fluid, and more importantly, its phase change, is crucial for removing substantial amounts of heat.

Traditional Cooling Methods

Consider the ubiquitous heat sink found in almost every desktop computer. These passive devices, typically made of aluminum or copper, rely on conduction to draw heat away from a component like a CPU and then use convection to dissipate that heat into the surrounding air. Fans are often added to heat sinks to force more air across the fins, dramatically increasing the rate of convective heat transfer.

Liquid cooling systems, utilizing pumps and radiators, take this a step further by circulating a coolant (usually water or a water-glycol mixture) to transport heat away from the source to a larger heat exchanger where it can be dissipated. These systems are generally more effective than simple heat sinks and fans, but are larger, more complex and have higher maintenance requirements.

While these traditional methods have served us well for many years, they are reaching their limits in many modern applications. As electronic devices become smaller and more powerful, the amount of heat generated per unit area increases dramatically. This presents a significant challenge for traditional cooling methods, which struggle to keep up with the increasing heat flux.

The thermal resistance of interfaces between components and heat sinks limits how quickly heat can be conducted away and physical space constraints limit the size of heat sinks and the size and number of fans that can be installed. Furthermore, single-phase liquid cooling systems are limited by the specific heat capacity of the coolant, restricting the amount of heat that can be absorbed per unit volume.

These limitations highlight the need for more efficient and compact cooling solutions. This is where two phase cooling technologies become highly desirable, promising significant improvements in heat transfer performance and enabling the development of smaller, more powerful electronic devices. Without more effective techniques, we’ll see diminishing returns in our devices and greater liklihood of thermal failure.

| Cooling Method | Heat Transfer Mechanism | Limitations |

|---|---|---|

| Heat Sink | Conduction, Convection | Limited by surface area, thermal resistance |

| Fan | Forced Convection | Noise, power consumption, size |

| Single-Phase Liquid Cooling | Convection | Coolant specific heat capacity, pump power, leakage risk |

Introducing Two Phase Cooling

Imagine a scenario where you need to cool down a high-powered electronic component, like the processor in a gaming laptop. Traditional methods like heat sinks and fans might struggle to keep up, causing the laptop to overheat and impacting performance. Now, what if there was a way to use a fluid that changes state from liquid to gas to absorb substantially more heat? That’s the core idea behind two phase cooling.

This method leverages the power of phase change – specifically, the transition of a liquid into a vapor. The basic principle is simple: when a liquid evaporates, it absorbs a tremendous amount of heat from its surroundings. This is because energy is required to break the intermolecular bonds holding the liquid together and transform it into a gas. This absorbed heat is known as latent heat, and it’s the key to the efficiency of two phase cooling systems.

Think of it like sweating on a hot day. Your body produces sweat, which is primarily water. As the sweat evaporates from your skin, it draws heat away from your body, cooling you down. Similarly, in two phase cooling, a special working fluid is used that readily evaporates at the operating temperature of the electronic component.

As this fluid evaporates, it pulls heat away from the component, keeping it cool. This vapor then moves away to a cooler section and condenses back into a liquid, releasing the stored heat to the surrounding environment. The liquid returns to the heat source, ready to start the cycle all over again. This cycle repeats, allowing for a highly efficient and continuous heat removal process.

The Physics of Phase Change

The key to understanding why two phase cooling is so effective lies in understanding *latent heat*. Latent heat refers to the energy absorbed or released during a phase change, such as when a liquid turns into a gas (evaporation) or a gas turns into a liquid (condensation), all without a change in temperature.

It’s a crucial concept because it explains why a relatively small amount of fluid can remove a significant amount of heat when it undergoes a phase transition.

Imagine boiling water. You can keep adding heat to the water, but the temperature will remain at 100°C (212°F) until all the water has turned into steam. The energy you’re adding isn’t increasing the water’s temperature; it’s being used to break the intermolecular bonds holding the water molecules together in a liquid state, allowing them to escape as a gas.

This energy required to cause that phase change, without a change in temperature, is the latent heat of vaporization. The value of the latent heat is dependent on the substance in question; some fluids will absorb more heat than others during a phase change.

This principle is directly applicable to *two phase cooling*. When a cooling fluid evaporates, it absorbs a large amount of heat (the latent heat of vaporization) from the hot component it’s cooling. The vapor then moves away, carrying that heat with it.

When the vapor condenses back into a liquid, it releases the latent heat, typically into a heat sink where it can be dissipated by fans or other cooling mechanisms. This cyclical process of evaporation and condensation allows for very efficient heat transfer. The entire process depends on the properties of a particular working fluid, and how easily it changes phase.

| Property | Description |

|---|---|

| Latent Heat of Vaporization | Energy absorbed when a liquid turns to gas. |

| Phase Change | Transition between liquid, gas and solid states. |

| Working Fluid | Fluid used in two phase cooling system. |

How Two Phase Cooling Works in Practice

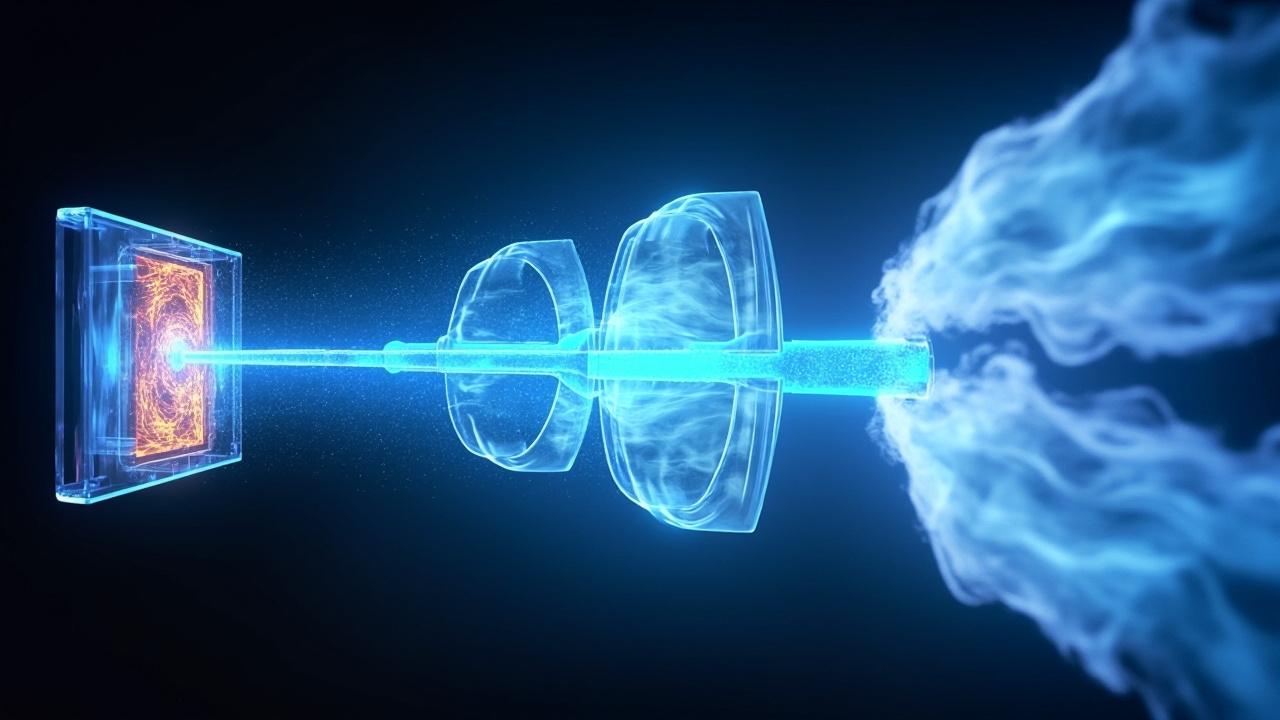

A typical two-phase cooling system relies on a closed-loop cycle, often implemented using devices like vapor chambers or heat pipes. These systems are ingeniously designed to capitalize on the latent heat of vaporization, efficiently transferring heat away from sensitive components. Imagine a sealed container with a working fluid inside.

At the heat source, such as a CPU, the liquid absorbs the heat, causing it to evaporate and transform into a vapor. This evaporation process is the heart of the cooling mechanism, as it soaks up a substantial amount of thermal energy.

Once the working fluid transforms into vapor, it travels to a cooler region of the system, typically a condenser. Here, the vapor releases the heat it absorbed and changes back into a liquid through condensation. This condensation process completes the cycle, and the liquid then returns to the heat source to repeat the process.

The continuous cycle of evaporation and condensation ensures a constant flow of heat away from the electronic component. This movement can be driven by pressure differences or capillary action within a wick structure inside the device, depending on the specific design of the system implementing two phase cooling.

Several factors are critical to the effectiveness of this cooling method. The selection of the working fluid is paramount, as it must possess suitable properties such as high latent heat of vaporization, appropriate boiling point, and chemical compatibility with the materials used in the system. Commonly used working fluids include water, refrigerants, and even specialized fluids tailored for specific applications.

The design of the heat transfer surfaces, both at the evaporator and condenser, also plays a crucial role in maximizing the heat transfer rate. Consider these components of the heat transfer process:

- Liquid absorbs heat from a heat source.

- Phase change from liquid to gas

- Vapor moves to a cooler location.

- Phase change from gas to liquid, heat is released.

- Liquid returns to heat source.

Advantages of Two Phase Cooling

Superior Heat Transfer

One of the most significant benefits of using two phase cooling lies in its remarkable heat transfer capabilities. Compared to traditional single-phase liquid cooling or even air cooling, two-phase systems can move substantially more heat away from a component for a given surface area. This increased efficiency stems from the utilization of latent heat.

During the phase change from liquid to vapor, a large amount of energy is absorbed without a significant increase in temperature. This contrasts sharply with single-phase cooling, where heat absorption is directly proportional to the temperature increase of the coolant. Because of this, two-phase cooling can maintain lower operating temperatures and better prevent thermal throttling within sensitive electronic components.

Compact and Lightweight Design

In many applications, space and weight are critical considerations. Two-phase cooling offers a significant advantage in this regard. Due to its superior heat transfer performance, a two phase cooling system can often achieve the same cooling capacity as a single-phase system while being considerably smaller and lighter.

This is particularly important in applications such as aerospace, where every gram counts, or in high-density electronics, where space is at a premium. The reduced size and weight not only make the overall device more portable and easier to integrate but can also lead to cost savings in terms of materials and manufacturing. Furthermore, the smaller footprint allows for more design flexibility, enabling engineers to optimize the layout of components and potentially improve overall system performance.

Enhanced Temperature Uniformity and Hotspot Mitigation

Beyond simply removing heat effectively, two-phase cooling excels at maintaining a more uniform temperature distribution across the cooled surface. This is particularly important for components with localized hotspots, such as CPUs or GPUs, where concentrated heat generation can lead to uneven temperatures and potential reliability issues. Two phase cooling helps to mitigate these problems by efficiently transporting heat away from the hot spots and distributing it more evenly across the cooling system.

This improved temperature uniformity not only enhances the performance and lifespan of the cooled components but also reduces the risk of thermal stress and premature failure. The ability to target and cool hot spots effectively makes two-phase cooling an ideal solution for demanding applications where precise temperature control is crucial.

Applications of Two Phase Cooling

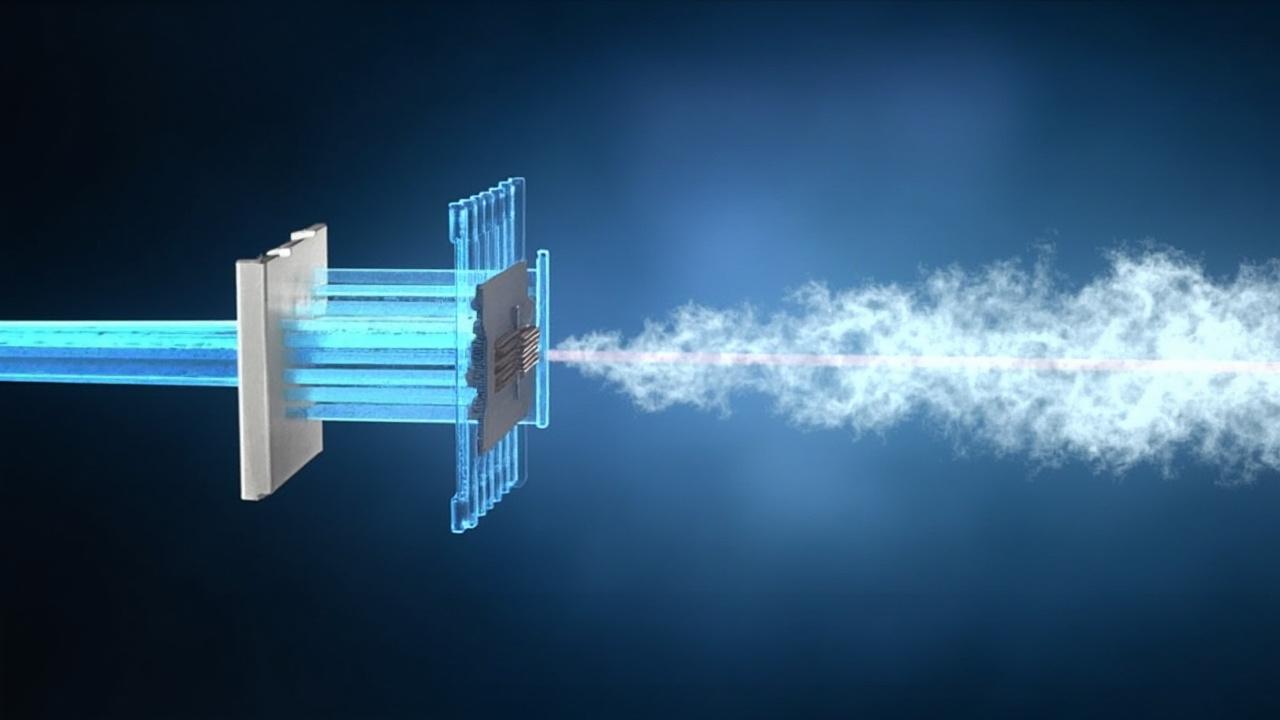

High-performance electronics are a major beneficiary of advancements in cooling technology, and this is especially true for two phase cooling. The ever-increasing demands on processors and graphics cards have led to significant heat generation, which, if not managed effectively, can lead to decreased performance, instability, or even permanent damage.

Traditional air cooling and even single-phase liquid cooling solutions often struggle to keep up with the thermal loads of these components, particularly in compact form factors like laptops and servers.

Therefore, manufacturers are increasingly turning to two-phase cooling solutions such as vapor chambers and heat pipes to dissipate heat more efficiently and maintain optimal operating temperatures. This allows for higher clock speeds, improved performance, and extended lifespan for these critical components.

Aerospace Applications

Beyond electronics, the unique demands of aerospace applications make two-phase cooling an indispensable technology. Satellites and spacecraft operate in a vacuum environment where traditional convective cooling is impossible. Heat generated by onboard electronics and other systems must be efficiently transferred to radiators for dissipation into space.

Two-phase cooling systems, with their high heat transfer coefficients and ability to operate in any orientation, provide a reliable and compact solution for managing thermal loads in these extreme environments. Furthermore, the lightweight nature of many two-phase cooling components is a significant advantage in aerospace, where every kilogram adds to launch costs. This makes it an attractive option for cooling sensitive equipment.

Emerging Applications

The benefits of two phase cooling are also extending into newer applications. Electric vehicles, for example, are generating a great deal of interest in using this technology to manage the heat produced by batteries and power electronics. Maintaining optimal battery temperature is crucial for maximizing range, performance, and lifespan of the battery.

Two-phase cooling can provide the necessary cooling capacity in a compact and lightweight package, making it a viable option for electric vehicle manufacturers. Furthermore, medical devices, such as MRI machines and high-powered lasers, are also exploring the use of two-phase cooling to maintain precise temperature control and ensure reliable operation. As technology continues to advance and generate more heat, the demand for efficient and effective cooling solutions like two-phase cooling will only continue to grow.

Challenges and Future Directions of Two Phase Cooling Technology

While offering many advantages, two phase cooling technology is not without its hurdles. One significant challenge lies in material compatibility with the chosen working fluids. Certain fluids, while possessing excellent thermal properties, can be corrosive or reactive with the materials used in the cooling system’s construction.

This can lead to degradation, leaks, and ultimately, system failure. Extensive research and testing are therefore crucial to ensure that the materials and fluids are chemically compatible over the long term, under varying operating conditions. This may involve the use of specialized coatings, alloys, or even the development of entirely new materials that can withstand the harsh chemical environments within the cooling system.

Another considerable factor impacting the widespread adoption of two phase cooling is the cost associated with implementing these complex systems. Compared to traditional cooling methods like heat sinks and fans, two-phase systems often require more intricate designs, specialized components (such as evaporators, condensers, and pumps), and sophisticated control mechanisms.

This translates into higher manufacturing costs, which can be a barrier for cost-sensitive applications. Further research and development efforts are needed to streamline the manufacturing process, reduce the cost of key components, and optimize system designs to make two phase cooling more economically viable for a broader range of applications.

Looking ahead, a promising avenue for improving the performance of two phase cooling systems involves the exploration of novel working fluids, such as nanofluids. Nanofluids are engineered fluids containing nanoparticles (typically metals or metal oxides) that are dispersed within a base fluid (like water or a refrigerant). These nanoparticles can significantly enhance the thermal conductivity and heat transfer characteristics of the fluid, leading to improved cooling performance.

However, challenges remain in ensuring the long-term stability and dispersion of nanoparticles within the fluid, as well as mitigating potential issues related to increased viscosity and pressure drop. Further research is needed to optimize the composition and properties of nanofluids for specific two phase cooling applications, and to develop reliable methods for their production and integration into cooling systems.

Conclusion

In summary, two phase cooling stands out as a highly effective solution to the ever-increasing challenges posed by heat generation across numerous industries. From the microprocessors powering our computers to the advanced electronics in aerospace applications, the ability to efficiently dissipate heat is critical for ensuring optimal performance and extending the lifespan of these crucial components.

The benefits of two-phase cooling, including its superior heat transfer capabilities, compact size, and ability to maintain uniform temperatures, make it an invaluable technology in the face of rising thermal demands.

The growing adoption of two phase cooling across diverse sectors signals its significance in shaping the future of technology. As industries continue to push the boundaries of performance and efficiency, the demand for advanced cooling solutions will only intensify.

Innovations like microchannel heat exchangers and the exploration of novel working fluids, including nanofluids, promise to further enhance the capabilities of two-phase cooling systems, unlocking new possibilities for thermal management in emerging applications like electric vehicles and cutting-edge medical devices.

Ultimately, the ongoing advancements in two phase cooling technology solidify its position as a key enabler of future innovations. By effectively addressing the pervasive challenge of heat, two-phase cooling paves the way for more powerful, reliable, and sustainable technologies across a wide range of industries. What applications of two-phase cooling pique your interest the most? Do you have any further questions about how this technology is revolutionizing thermal management?

Frequently Asked Questions

What is two-phase cooling and how does it differ from single-phase cooling?

Two-phase cooling utilizes the latent heat of vaporization of a fluid to dissipate heat. This means the coolant undergoes a phase change from liquid to vapor, absorbing a significant amount of heat in the process at a constant temperature.

Single-phase cooling, on the other hand, relies solely on the sensible heat capacity of the fluid, where the temperature of the coolant rises as it absorbs heat without changing its phase.

What are the advantages of using two-phase cooling over traditional cooling methods?

Two-phase cooling offers several advantages including significantly higher heat transfer coefficients compared to traditional methods, enabling more efficient cooling of high-heat-flux components. This allows for more compact and lighter cooling systems. It also provides better temperature uniformity due to the phase change occurring at a relatively constant temperature, preventing hot spots.

What are the different types of two-phase cooling methods (e.g., pool boiling, flow boiling)?

Various two-phase cooling methods exist, each with its specific application. Pool boiling involves a heated surface submerged in a stationary pool of liquid, with bubbles forming and rising away.

Flow boiling occurs when the liquid coolant is forced through a channel, undergoing phase change as it flows. Spray cooling utilizes a spray of fine liquid droplets onto the hot surface to achieve rapid cooling.

What fluids are commonly used as coolants in two-phase cooling systems?

Several fluids are used in two-phase cooling systems, selected based on their thermophysical properties and compatibility with the system materials. Common coolants include water, which offers high latent heat of vaporization, and refrigerants like R-134a or HFOs, which are often used in applications requiring lower operating temperatures. Ammonia is also utilized in some industrial applications.

What are the key components of a typical two-phase cooling system?

A typical two-phase cooling system consists of several crucial components. An evaporator is where the coolant absorbs heat and undergoes phase change. A condenser rejects the heat from the vaporized coolant, causing it to condense back into a liquid.

A pump or compressor circulates the coolant through the system. An expansion valve or throttling device regulates the flow of the liquid coolant. Reservoirs and accumulators manage the coolant inventory and pressure fluctuations.